Quick Details

- ProName: Polyurethane foam

- CasNo: 9009-54-5

- Molecular Formula: Unspecified

- Appearance: Yellowish transparent liqiud or waxy

- Application: PU FOR SHOE SOLE

- PackAge: 225kg/drum with pallets and shrink-wra...

- Purity: 100%

- Storage: kept in sealed in the shady and ventil...

- Transportation: dry

- LimitNum: 10 Metric Ton

Superiority

ONE TYPE OF OUR PRODUCT :

Typical properties of PU matrix

Name of product Apperance Viscosity(mPa?/40℃) Density(g?cm/40℃) Package(kg)

A-8170 li…

Details

ONE TYPE OF OUR PRODUCT :

Typical properties of PU matrix

Name of product Apperance Viscosity(mPa?/40℃) Density(g?cm/40℃) Package(kg)

A-8170 liquid 1000-1400 1.01-1.02 18

B-8290 Yellowish Transparent Liquid or Waxy 600-800 1.08-1.2 20

Material preheat

A-8170 Preheated at 50-60℃ for 6-8 hours

B-8290 Preheated at 50-60℃ for 8-12 hours

Typical processing parameters & Reaction parameter

Items A/B Materials

Temperature(℃) A+C/B Mix ratio (by weight) Cream

Time

(s) End of rise time(s) Free rise foam density(g/cm3) Mold temperature(℃) Demold time(min)

Parameter 40-45/38-42 100/101-102 8-10 60-70 0.24-0.26 45-55 5-7

The adding content of C-2 should be 250g±20/18kg

The adding content of water should be 0-40g/18kg according to the reality

The adding content of hardener should be 0-400g/18kg according to the reality

Physical properties

Items Molded Density(g/cm3) Hardness(shore A) Tensile strength(Mpa) Elongation(%) Tear Strength(kN/m) Flexing resistance

(Break length,4mm)

Room temperature

Physical

properties 0.50-0.70 55-68 7.5-9.0 340-450 24-33 40,000times no increasing

Demold time may be prolonged with the increase of sole thickness.

These physical date are acquired by testing a sample of 6mm thick.

Data listed above are just for reference, The detail date are subjected to practical production, If other request for Physical properties, please contact us.1.high strength and cohesive force, good abrasion resistance and skid resistance

2.Double density sole system

Safty shoes and Army boots Characteristic high strength and cohesive force, good abrasion resistance and skid resistanceApplication Double density sole system for common safety shoes and one-step forming casual shoesTypical properties of PU matrix Name of productsAppeara1.Low density and high hardness, good surface after coating 2.can adjust the hardnesss by yourself easily

Characteristic Low density and high hardness, good surface after coating Application Sole for woman high-heeled shoes out sole Molded Density (g/cm3)0.30-0.40 Typical properties of PU matrix Name of productsAppearanceViscosity (mPa·s/40°C)Density (g·cm-3/40°C)Package(kg)A-9007cream white liquid1500~25001.01~1.02225B-6088Yellowish transparent liquid or waxy600~8001.08~1.2225 Materials preheatA-9007 preheated at 50~60°C for 16~18 hours B-6088 preheated at 50~60°C for 18~20 hoursTypical processing parameters & Reaction parameter ItemsA/B Materials Temperatures(°C)A+C/B Mix ratio(By weight) Cream Time (s)End of Rise Time (s)Free Rise Foam Density(g/cm3) Mold Temperature(°C)Demold Time(min)Parameter40~45/38~42100/916~850~600.14~0.2055~655~7 The adding content of C-2 should be 220g±5g/18kg The adding content of water and hardener should be added according to the realityPhysical properties ItemsMolded Density (g/cm3)Hardness(Shore A )Tensile strength(MPa)Elongation(%)Tear Strength(kN/m)Flexing resistance(room temperature)DIN Abrasion(mm)Physical properties0.30-0.4052~624.0-7.5290-36018-30No crack 180-240 Demold time may be prolonged with the increase of sole thicknessThese physical data are acquired by testing a sample of 6mm thick.Data listed above are just for reference. The detail data are subjected to practical production. If other requests for Physical properties, please contact us. we are the the leading manufacture of polyurthane resins in china,the packge as below

when injection finished,we close the mold and wait for 3-4 minutes,then we can get the beactidul shoe sole as below.

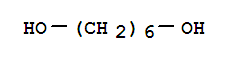

![Poly[oxy-1,2-ethanediyloxy-1,2-ethanediyloxy(1,6-dioxo-1,6-hexanediyl)]](http://www.lookchem.com/300w/2010/077/25036-49-1.jpg)